Steel Silo Design

Some details in the early design stage can determine the overall quality of the steel silo. Reasonable design work can guarantee a long service life for the steel silo.

Preparations Before Designing

Designers need to do a series of preparations before they start designing a steel silo.

First, they need to learn where the customer is going to use the steel silo ( are they going to use it for storage, or for transportation, or in a production line? ) and what are they going to store. So they can select correct auxiliary equipment for the silo, and create a detail storage solution.

Second, they need to go to the silo project location to observe the site environment, learn the local geological conditions and annual weather data. It is necessary to strictly survey the proposed site for the steel silo in order to obtain reliable and actual data of the soil density and its bearing capacity.

The designers need to fully calculate the load that the steel silo is subjected to when its capacity is saturated, in order to design the bearing capacity of the foundation.

Third, it is also necessary to strictly calculate the difference between the load of the large steel silo and the bearing capacity of the foundation.

After calculating the difference value between the load of the steel silo and the bearing capacity of the foundation, the designers must increase the soil density of the foundation soil to meet the required foundation bearing capacity of the large steel silo in the range of the allowable value of the compressive modulus of the foundation.

A subsidence zone should be set before the construction start. The designers must make sure that the magnitude of sinking of large steel silo foundations is exactly the same as the height of the subsidence zone below the large steel silo. Otherwise, the silos will not be able to sink uniformly.

Layout Design of Steel Silos

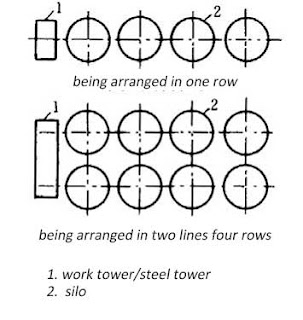

In the layout design of steel warehouses, designers need to consider the construction technology, terrain, engineering geology, total investment, and many otehr elements. They will draft several plans, and select the most appropriate one after comparison.

Usually, the distance between two silos needs to be more than 500mm. But the distance can be determined by the silos’ base design if they are applying independent base. Besides, the space between every two silos should be big enough to load necessary auxiliary equipment.

Steel Silo Structure Selection Principle

Steel silo structure can be divided into six basic parts: building above top of silo, silo top, silo wall, silo bottom, supporting structure of silo bottom, and foundation. Here are some principles need to follow the design of a steel silo’s structure:

- The process conveyor equipment and operation and maintenance platform set on the silo should adopt open steel structure channels. When there are special requirements, closed corridors can also be used.

- The roof of steel silo should be designed as a conical shell with top and under tube or a truncated cone space truss structure.

- When the silo wall is designed to corrugated plate or spiral bead plate, the construction material should be hot-dip galvanized or alloy steel plate.

- The bottom of steel cement silo can apply concrete structure or steel structure to support the silo body.For silos with a diameter below 10 meters, it’s better to apply column supporting structure, wall supporting structure or cone bottom structure. For those with a diameter more than 12m, flat bottom is the optimum structure.

评论

发表评论